Blackening merupakan sebuah proses "Penghitaman" atau pemberian

warna hitam pada sebagian

permukaan besi (metal), steel dsb dengan tujuan dekoratif (merubah

penampilan dari permukaan besi sehingga lebih menarik). Juga bertujuan

untuk meningkatkan ketahanan terhadap korosi ringan,

Untuk mencapai

ketahanan maksimal, produk yang telah di Blackening dapat diberikan (dioles)

dengan Rust Preventive Oil.

Setelah di blackening dan diberi rust preventive oil :

Hasil dari

proses Blackening yang baik, tidak mempengaruhi dimensi

dari material dan mewarnai secara seragam untuk tiap sudut, termasuk bagian

dalam lobang- lobang yang tak terlihat (ideal untuk part-part kecil).

Our Product :

Dia Black, packaging : 25 Kg/Bag

Aplikasi :

a. Larutkan

Produk Blackening (DIA BLACK) dan Air, dengan perbandingan 55% : 45%

b. Panaskan

Suhu larutan ± 140°C

c. Celupkan

metal yang akan di proses, selama 5 - 15 menit (tergantung tingkat kehitaman

yang diinginkan).

d. Bilas

dengan air, untuk menghindari kontaminasi ke proses selanjutnya.

e. Jika

menginginkan hasil yang lebih mengkilap, tidak ada bercak seperti white rust

(tampilan mirip bedak putih), dan ketahanan terhadap korosi yang lebih

maksimal, tambahkan Rust

Preventive Oil (Diacote RP-91) pada

part.

Urutan Proses

:

Degreasing -- Water Rinsing -- Blackening -- Water Rinsing -- Hot Water

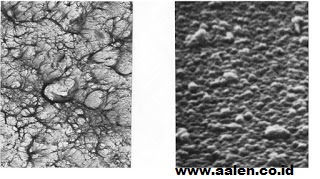

Perbedaan dan

persamaan dengan proses Manganese Phosphate :

- Pada

Manganese phosphate, di peruntukkan untuk Part-part yang membutuhkan Friksi

(gesekan), sedangkan pada Part yang di Blackening tidak, hanya berfungsi untuk

menghitamkan saja (dekoratif).

- Proses pada

Manganese Phosphate menggunakan suhu yang relatif lebih rendah, yaitu 96-100°C dan additive berupa steel wool,

sedangkan untuk Proses Blackening membutuhkan suhu yang relatif lebih tinggi,

yaitu ± 140°C.

Untuk informasi lebih lanjut dapat menghubungi kami :

PT. Aalen Chemicals Indonesia

Jl. Pulobuaran III Blok G3

Kawasan Industri JIEP, Pulogadung

Jakarta Timur

Tlp : 021-46830522

Website : www.aalen.co.id

Email : aalen.chemicals@gmail.com, aalen@cbn.net.id