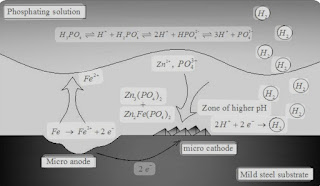

Phosphating adalah proses perlakuan

terhadap logam (besi, galvanized atau aluminium) menggunakan asam phosphate dan

senyawa lainnya dimana permukaan logam bereaksi secara kimia dengan media asam

phosphate tersebut membentuk lapisan kristal phosphate yang tidak larut yang

melindungi permukaan logam secara keseluruhan.

Mengapa proses phosphating dan metal pre-treatment penting untuk dilakukan ?

a. Membersihkan metal/ logam

(Degreasing)

b. Persiapan untuk proses pengecatan

c. Mengurangi reaksi metal/ cat

d. Meningkatkan ketahanan terhadap korosi

e. Meningkatkan ketahanan terhadap Blister

Faktor-faktor yang mempengaruhi Hasil Phosphating :

-Metode cleaning yang digunakan

-Penggunaan surface conditioning

-Metode aplikasi yang digunakan (Spray atau

dipping)

-Suhu, konsentrasi dan waktu

-Modifikasi

komposisi larutan

a. Spray (Penyemprotan, dengan bantuan mekanik ke arah

benda kerja).

Product list and function :

1. Diafos 1000 Prep ;

Tri-cationic phosphate process for spray application Make up

2. Diafos 1000 ALIM ;

Tri-cationic phosphate process for spray application Repleshing

3. Diafos 1030 ALIM ; Low

Temperature Zinc Phosphate Process

4. Diafos 1222 ALIM ;

Immersion Zinc Phosphate Replenishing

5. Diafos 1222 Prep ;

Immersion Zinc Phosphate Make up

6. Diafos I-5000 ; Iron

phosphating for spray & immersion application

7. Diafos I-5050 ; Iron

phosphating for spray application

b. Immersion (Dipping, pencelupan), benda kerja

dicelupkan ke dalam bak yang berisi larutan Phosphating

Product list and function:

1. Diafos 2000-1 ALIM; Tri-cationic phosphate process for

immersion application Replenishing

2. Diafos 3000 Prep ; Zinc phosphate for steel cold

forming Make up

3. Diafos 3000 ALIM ; Zinc phosphate for steel cold

forming Replenishing

Beberapa type phosphating :

a. Satu Kation :

- Zinc Phosphating (Zn

Phosphate)

- Manganese Phosphating (Mn Phosphate)

- Iron Phosphating (Fe-Phosphate)

b. Dua kation

- Zinc dan Nickel Phosphate

c. Tiga Kation :

- Perpaduan Zinc, Manganese dan Nickel Phosphate

- Manganese Phosphating (Mn Phosphate)

- Iron Phosphating (Fe-Phosphate)

b. Dua kation

- Zinc dan Nickel Phosphate

c. Tiga Kation :

- Perpaduan Zinc, Manganese dan Nickel Phosphate

a. Satu Kation :

- Iron phosphating :

Advantage :

- Coating Thickness : 200 - 800 nm

- No heavy metalls

- Medium energy consumption

- Medium cost for : waste disposal, cleaning and chemicals

- Result of phosphating : Rainbow coating (visual)

Simple process of Iron phosphating in Customer :

a. Degreasing

b. Rinsing

c. Iron Phosphating

d. Rinsing

e. Drying

b. Dua Kation :

- Zn Phosphating:

- Zn Phosphating:

Diafos 1030, Packaging : 30 Kg/Can

A typical process of Zinc phosphating in Customer :

a. Degreasing

b. Rinsing

c. Activation

d. Phosphating

e. Rinsing

f. Post Treatment

g. Drying

c. Tiga Kation :

-Zn Phosphating: c. Tiga Kation :

Advantage :

- Coating

thickness 2.000 - 10.000 nm

- High corrosion protection

- Result of phosphating : Grey coating (visual)

-Metode aplikasi Phosphating ada 2, yaitu dipping (celup) atau spray (semprot):

A typical process of Zinc phosphating in Customer :

a. Degreasing

b. Rinsing

c. Activation

d. Phosphating

e. Rinsing

f. Post Treatment

g. Drying

For more details, please contact us:

PT. Aalen

Chemicals Indonesia

Jl Pulobuaran

III Blok G3,

Kawasan

Industri JIEP, Pulogadung

Jakarta Timur

Tlp :

021-46830522

Website :

www.aalen.co.idEmail : aalen.chemicals@gmail.com, aalen@cbn.net.id

No comments:

Post a Comment